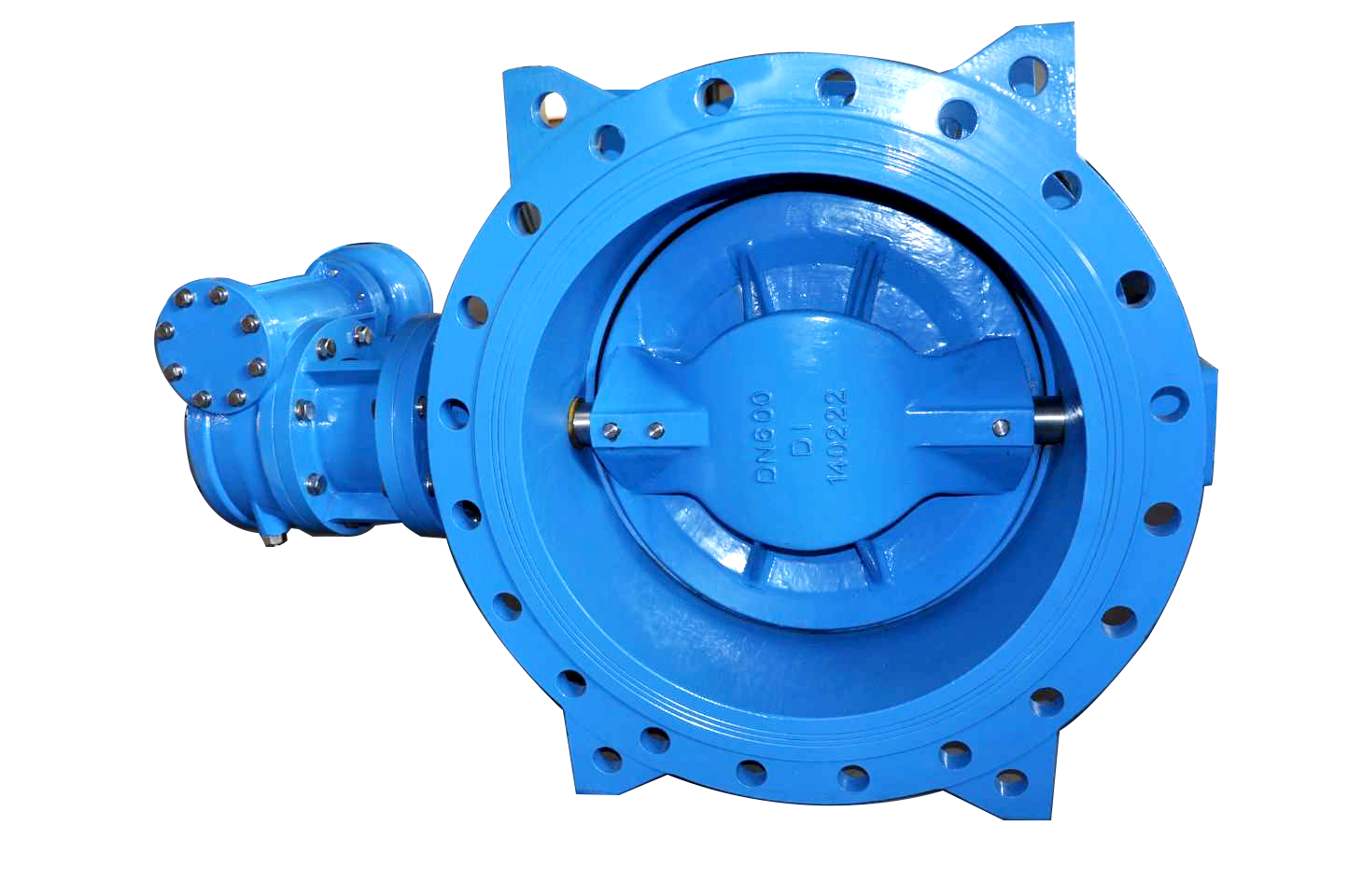

Centerline Butterfly And Eccentric Butterfly Valve

The rotation center of the butterfly plate and the sealing position of the valve seat form two eccentric distances, which ensure that the butterfly plate is quickly separated from the valve seat during the switch rotation process, so that there is no contact between the butterfly valve and the seal during the working process, which reduces Wear and tear, and more importantly, our G-type valve seat applies the patented technology of Handa (HD). Through a large number of calculations, trial and error, and actual measurement in domestic applications, it has proved that the high-performance butterfly valve has "zero leakage and 100% leakage". The effect of “ten thousand times service life”, our G-type sealing valve seat, from the cross-sectional view, we can see that the contact shape between the butterfly plate of our butterfly valve and the sealing surface of the valve seat is like a simply supported beam structure, when the butterfly plate squeezes towards When the sealing surface of the valve seat, the sealing surface has a flexible deformation position and space, so when the medium pressure changes and the valve seat moves axially, the PTFE valve seat will not be deformed by cold flow. In this way, the butterfly valve will open and close. The sealing surface of the seat will not be squeezed and deformed, and the service life of the valve seat is particularly long.

03

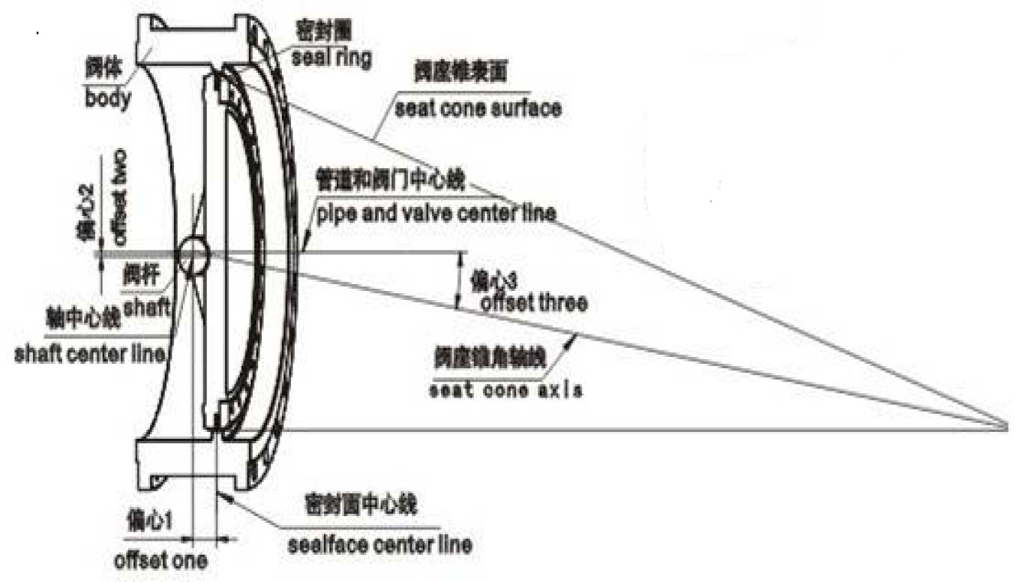

Triple eccentricity To withstand high temperatures, hard seals must be used, but the leakage rate is high; for zero leakage, soft seals must be used, but they are not resistant to high temperatures. In order to overcome the contradiction of double eccentricity, a third eccentricity was carried out. Its structural feature is that while the double eccentric valve stem axis position is eccentric, the conical axis of the gate sealing surface is skewed to the cylinder axis of the body, that is to say, after the third eccentricity, the sealing section of the gate is not Furthermore, it is a true circle, but an ellipse, and the shape of the sealing surface is therefore asymmetric, one side is inclined to the center line of the body, and the other side is parallel to the center line of the body. The highest advantage of this third eccentricity is that it fundamentally changes the sealing structure. It is no longer a positional seal, but a torsion seal, that is, it does not rely on the elastic deformation of the valve seat, but completely relies on the contact surface pressure of the valve seat to achieve the seal. Therefore, the problem of zero leakage of the metal valve seat is solved in one fell swoop, and because the contact surface pressure is proportional to the medium pressure, the high pressure and high temperature resistance is also solved.

Comments

Post a Comment